Umurongo wumye wa minisiteri yumye CRL-2

Ibicuruzwa birambuye

Intangiriro

Umurongo wumusaruro wumye

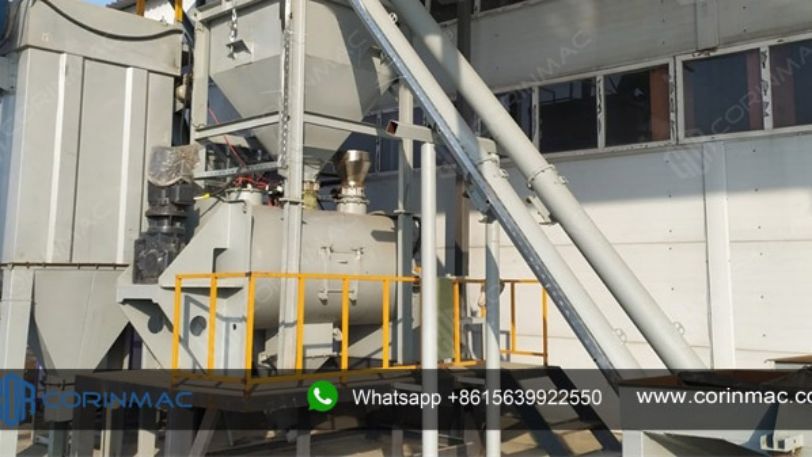

Umurongo wa Vertical mortar umurongo CRL, uzwi kandi nk'umurongo usanzwe wa minisiteri, ni ibikoresho byuzuye byo gutunganya umucanga wuzuye, ibikoresho bya sima (sima, gypsumu, nibindi), inyongeramusaruro zitandukanye nibindi bikoresho mbisi ukurikije resept yihariye, kuvanga hamwe na mixer, hamwe no gupakira muburyo bwa pompe yumye yumye, harimo silo yo kubika ibikoresho bibisi silo, convoyeur ya screw, ipima ipima, sisitemu yo kongeramo ibikoresho, icyuma cyindobo, icyuma kibanziriza kuvanga, kuvanga, imashini ipakira, gukusanya ivumbi hamwe na sisitemu yo kugenzura.

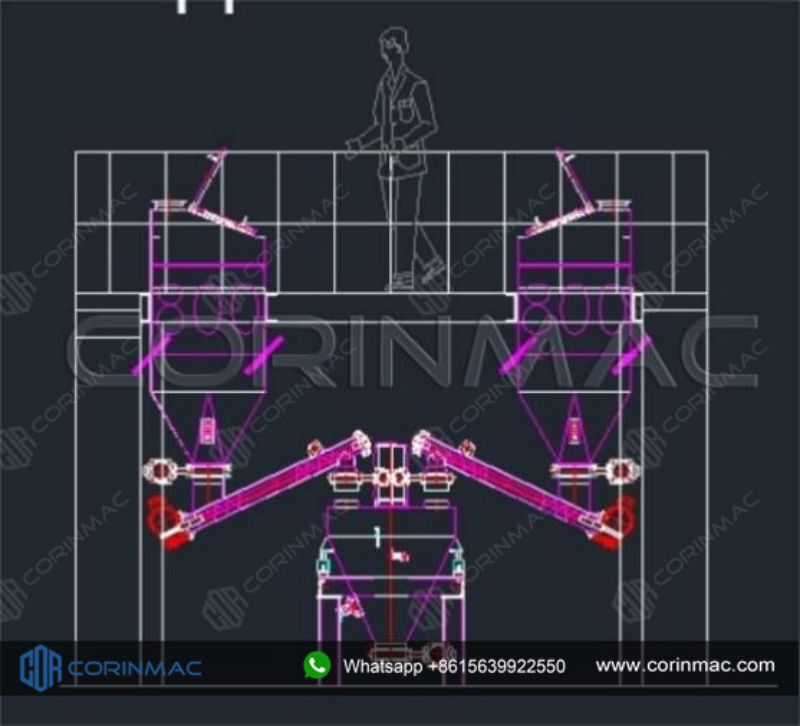

Izina rya vertical mortar production line ituruka kumiterere yayo.Imashini ibanziriza kuvanga, sisitemu yo kongeramo ibikoresho, kuvanga hamwe nimashini ipakira byateguwe kumurongo wibyuma kuva hejuru kugeza hasi, bishobora kugabanywamo igorofa imwe cyangwa amagorofa menshi.

Imirongo ya Mortar izatandukana cyane kubera itandukaniro mubisabwa mubushobozi, imikorere ya tekiniki, ibikoresho bigize urwego na automatike.Gahunda yumusaruro wose irashobora gutegurwa ukurikije urubuga rwabakiriya na bije.

CRL-2 ikurikirana yumurongo urimo

• Ibikoresho byo guterura no gutwara ibikoresho;

• Ibikoresho byo kubika ibikoresho

• Kunyeganyeza ecran

Sisitemu yo gupakira no gupima

Imashini ivanga nogupakira

Sisitemu yo kugenzura

• Ibikoresho bifasha

Umuyoboro

Imiyoboro ya kaburimbo ikwiranye no kugeza ibikoresho bitagaragara nka poro yumye, sima, nibindi bikoreshwa mu gutwara ifu yumye, sima, ifu ya gypsumu nibindi bikoresho fatizo kubivanga kumurongo w’ibicuruzwa, no gutwara ibicuruzwa bivanze kuri ibicuruzwa byarangiye.Impera yo hepfo ya convoyeur ya screw yatanzwe nisosiyete yacu ifite ibikoresho byo kugaburira, kandi abakozi bashyira ibikoresho bibisi muri hopper.Imigozi ikozwe mu byuma bivanze, kandi ubunini bujyanye nibikoresho bitandukanye bigomba gutangwa.Impera zombi za shitingi zifata uburyo bwihariye bwo gufunga kugirango bigabanye ingaruka zumukungugu.

Ibikoresho byo kubika ibikoresho

Umusenyi

Umusenyi wumusenyi ugizwe ahanini numubiri wa hopper (ingano nubunini bwumubiri wa hopper byateganijwe ukurikije ibikenewe nyabyo), ibyuma bifasha ibyuma, vibrateri, hamwe nipima urwego, nibindi. Kugirango uzigame ikiguzi cyo gutwara, uyikoresha irashobora kuyikora mugace, kandi tuzatanga igishushanyo nigishushanyo mbonera.

Kunyeganyega

Mugaragaza kunyeganyega bikoreshwa mugushungura umucanga mubunini bwifuzwa.Umubiri wa ecran ukoresha imiterere ifunze neza, ishobora kugabanya neza ivumbi ryakozwe mugihe cyakazi.Mugaragaza ibyapa byumubiri, ibyapa byohereza amashanyarazi nibindi bikoresho bikozwe mubyuma byujuje ubuziranenge byibyuma, hamwe nimbaraga zitanga umusaruro nubuzima bwa serivisi ndende.

Sisitemu yo gupima no gupima (ibikoresho nyamukuru ninyongera)

Ibikoresho by'ingenzi bipima hopper

Icyuma gipima kigizwe na hopper, ikariso yicyuma, hamwe na selile yimitwaro (igice cyo hepfo yicyuma gipima gifite ibyuma bisohora).Icyuma gipima gikoreshwa cyane mumirongo itandukanye ya minisiteri kugirango bapime ibintu nka sima, umucanga, ivu ryisazi, calcium yoroheje, na calcium iremereye.Ifite ibyiza byo kwihuta byihuse, gupima neza, gupima ibintu byinshi, kandi irashobora gukoresha ibikoresho byinshi.

Sisitemu yo gutunganya sisitemu

Imashini ivanga nogupakira

Imashini yumye

Ivanga rya minisiteri yumye nibikoresho byibanze byumurongo wa minisiteri yumye, bigena ubwiza bwa minisiteri.Imvange zitandukanye za minisiteri zirashobora gukoreshwa ukurikije ubwoko bwa minisiteri.

Imashini imwe ya shaft isaranganya ivanga

Tekinoroji yo kuvanga isuka ivangwa cyane cyane mubudage, kandi ni mixer ikunze gukoreshwa mumirongo minini yumye ya poro yumye.Isoko yo kugabana isuka igizwe ahanini na silinderi yo hanze, igiti kinini, imigabane yo guhinga, hamwe nu mugabane wo guhinga.Kuzenguruka kw'igiti nyamukuru gitwara umuhoro umeze nk'isuka kuzunguruka ku muvuduko mwinshi wo gutwara ibikoresho kugenda byihuse mu byerekezo byombi, kugira ngo ugere ku ntego yo kuvanga.Umuvuduko ukurura urihuta, kandi icyuma kiguruka gishyirwa kurukuta rwa silinderi, rushobora gukwirakwiza vuba ibikoresho, kuburyo kuvanga ari byinshi kandi byihuse, kandi ubwiza bwo kuvanga buri hejuru.

Igiti kimwe cya shaft isaranganya ivanga (umuryango muto wo gusohora)

Igice kimwe cya shaft isuka ivangavanga (umuryango munini wo gusohora)

Igiti kimwe cya shaft isaranganya ivanga (Ifunguro ryihuta)

Ibicuruzwa

Ibicuruzwa byarangiye byuzuye ni silo ifunze ikozwe mu byuma bivangwa no kubika ibicuruzwa bivanze.Hejuru ya silo ifite icyambu cyo kugaburira, sisitemu yo guhumeka hamwe nigikoresho cyo gukusanya ivumbi.Igice cya cone cya silo gifite vibatori ya pneumatike hamwe nigikoresho kimena ibyuma kugirango birinde ibikoresho guhagarikwa muri hopper.

Imashini ipakira imifuka

Dukurikije ibisabwa nabakiriya batandukanye, turashobora gutanga ubwoko butatu bwimashini zipakira, ubwoko bwimodoka, ubwoko bwumuyaga nubwoko bureremba bwikirere kugirango uhitemo.Module yo gupima nigice cyibanze cyimashini ipakira igikapu.Icyuma gipima, kugenzura ibipimo hamwe nibikoresho bya elegitoroniki bikoreshwa mu mashini yacu ipakira byose ni ibirango byo mu rwego rwa mbere, bifite intera nini yo gupima, ibisobanuro bihanitse, ibitekerezo byoroshye, kandi ikosa ryo gupima rishobora kuba ± 0.2%, rishobora kuzuza neza ibyo usabwa.

Kugenzura Inama y'Abaminisitiri

Ibikoresho byavuzwe haruguru nubwoko bwibanze bwubu bwoko bwumurongo.

Niba ari ngombwa kugabanya ivumbi mu kazi no kunoza imikorere y’abakozi, hashobora gushyirwaho umukungugu muto.

Muri make, turashobora gukora ibishushanyo mbonera bitandukanye hamwe nibishusho dukurikije ibyo usabwa.

Intambwe yo kwishyiriraho kuyobora

Igishushanyo

Ibicuruzwa byacu

Ibicuruzwa bisabwa

Amashanyarazi yumye hamwe ningufu nkeya kandi muraho ...

Ibiranga ibyiza:

1. Ukurikije ibikoresho bitandukanye bigomba gukama, hashobora gutorwa imiterere ikwiye ya silinderi.

2. Igikorwa cyoroshye kandi cyizewe.

3. Inkomoko zitandukanye z'ubushyuhe zirahari: gaze gasanzwe, mazutu, amakara, ibice bya biomass, nibindi.

4. Kugenzura ubushyuhe bwubwenge.

Igikorwa gihamye hamwe nubushobozi bunini bwo gutanga b ...

Lifte y'indobo ni ibikoresho bikoreshwa cyane mu guhererekanya ibintu.Ikoreshwa muguhindura verticale yifu, ibikoresho bya granulaire ninshi, hamwe nibikoresho byangiza cyane nka sima, umucanga, amakara yubutaka, umucanga, nibindi. Ubushyuhe bwibintu buri munsi ya 250 ° C, kandi uburebure bwo guterura bushobora kugera Metero 50.

Ubushobozi bwo gutanga: 10-450m³ / h

Umubare w'ikoreshwa: kandi ukoreshwa cyane mubikoresho byo kubaka, ingufu z'amashanyarazi, metallurgie, imashini, inganda zikora imiti, ubucukuzi bw'amabuye y'agaciro n'inganda.

reba byinshi

Ibikoresho byingenzi bipima

Ibiranga:

- 1. Imiterere ya hopper ipima irashobora gutoranywa ukurikije ibikoresho bipima.

- 2. Ukoresheje ibyuma bisobanutse neza, gupima nukuri.

- 3. Sisitemu yo gupima byimazeyo, ishobora kugenzurwa nibikoresho bipima cyangwa mudasobwa ya PLC

Umuyoboro uramba kandi woroshye

Ibiranga :

Igaburo ry'umukandara rifite ibikoresho byihuta byihuta bigenga moteri, kandi umuvuduko wo kugaburira urashobora guhinduka uko bishakiye kugirango ugere ku ngaruka nziza yo gukama ubutare ibindi bisabwa.

Ifata umukandara wa skirt convoyeur kugirango wirinde kumeneka ibintu.

reba byinshi

Umurongo wumye wa minisiteri yumye CRL-3

Ubushobozi:5-10TPH;10-15TPH;15-20TPH

reba byinshi

Amashanyarazi atatu azunguruka yumye hamwe nubushyuhe bwinshi effi ...

Ibiranga:

1. Ubunini muri rusange bwumye bwagabanutseho hejuru ya 30% ugereranije nibisanzwe byuma byuma byuma byuma, bityo bikagabanya gutakaza ubushyuhe bwo hanze.

2. Ubushuhe bwumuriro wokwikingira ubwinshi buri hejuru ya 80% (ugereranije na 35% gusa kumashanyarazi asanzwe), kandi ubushyuhe bwumuriro buri hejuru ya 45%.

3. Bitewe no kwishyiriraho ibice, umwanya wo hasi wagabanutseho 50%, naho ibikorwa remezo bigabanukaho 60%

4. Ubushyuhe bwibicuruzwa byarangiye nyuma yo gukama ni dogere 60-70, kuburyo bidakenera ubukonje bwiyongera kugirango bukonje.